Description

Polyurethane components with extreme temperature resistance

.

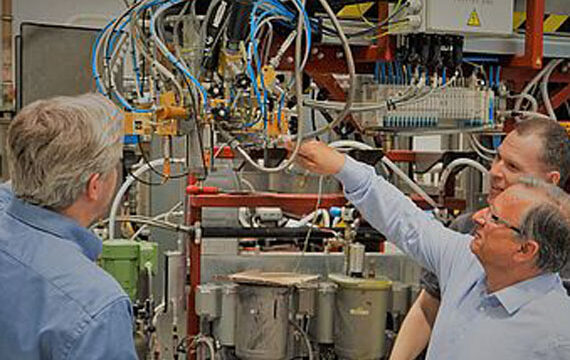

Based on many years of experience and contacts in the field of storage and manipulation of high-quality sheet metal coils, Polytec Industrial received a customer request that required a technological leap in terms of temperature resistance of polyurethane elastomers. 150°C at a load of up to 40 tons was the target. Until then, the limit of polyurethane elastomers had been around 80°C. However, the developers at the site in Marchtrenk, Upper Austria, were not intimidated by this.

They immediately began building a special device to simulate the desired temperature and pressure load and thus create a reliable test environment. Parallel to the intensive development and testing phase at Polytec Elastoform in Marchtrenk, we started field tests at a well-known steel manufacturer and logistics company.

Why are coils weighing tons stored on components made of polyurethane?

Especially for high quality steel sheets for the automotive industry, but also for soft aluminum sheets, the integrity of the raw material is an absolute necessity. Every linear meter that cannot be used for the finished product due to pressure marks caused by improper storage means a high loss. If a coil of aluminum is stored on a support of the same material, it often happens that the first 15 windings cannot be used for production. With a diameter of up to 2,400 millimeters, this represents a material loss of over 100 meters. When stored on mats made of polyurethane, this loss is reduced to a minimum.

In recent years, Polytec Industrial has implemented a number of successful projects that support proper storage as well as safe transport of coils. For example, the use of polyurethane can prevent fretting corrosion and protect valuable meters of these high-quality materials.

Whole solutions from Polytec Industrial.

High-quality sheet is formed during cold rolling. In the case of aluminum, the coils leave the plant at around 150°C. Since the sensitive coils cannot simply be placed on the floor to cool, gentle storage is especially important during this phase. Our heat-resistant polyurethane components enable a smooth production process – the coils do not have to remain in the plant to cool down, but can be immediately placed on the polyurethane mats and moved to their storage location.

Challenge us!